TODAY'S SPRAY & GEL VACCINATION PRACTICES

In today's poultry industry,

conventional manual sprayers struggle to ensure optimal vaccination quality due to multiple factors. The pivotal step of vaccinating day-old chicks is compromised, jeopardizing chances to get full vaccine take.

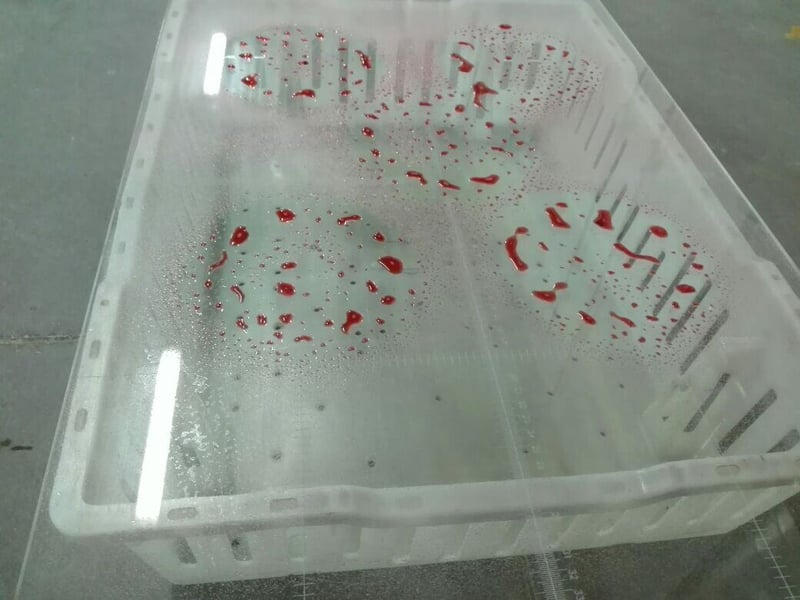

Low spray vaccination homogeneity

Currently, all manual sprayers are aquipped with conical spray nozzles. This type of equipment cannot ensure proper vaccination quality because it is impossible to guarantee uniformity across all animals. Unsprayed areas and overlaping are nearly inevitable phenomena with these types of devices.

Operator dependant

Vaccination using a manual sprayer is entirely dependent on the operator's focus. If the operator removes the crates before the completion of spraying, the entire dose is not properly distributed.

High spray quality without automation

Thanks to its flat nozzle system, the Smart Hatch Spray & Gel is the only stand-alone machine ensuring a high level of spray homogeneity. Droplet size is controlled by the nozzles, and their adjustment ensures consistent coverage from start to finish of the crate. The volume dispense, combined with arm movement, all managed by the machine's electronics, guarantees that each bird, receive uniformly full dose.

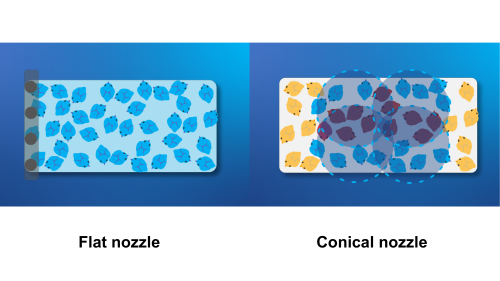

Comparison between

Flat nozzle / Conical nozzle distribution

Comparison of spray application between Flat Nozzles and Conical Spray Nozzles in Standard Chick Crates.

Article

Correct spray vaccination is critical for effective IB flock immunisation.

Thanks to its flat nozzle system, the Smart Hatch Spray & Gel is the only stand-alone machine ensuring a high level of spray homogeneity. Droplet size is controlled by the nozzles, and their adjustment ensures consistent coverage from start to finish of the crate. The volume dispense, combined with arm movement, all managed by the machine's electronics, guarantees that each bird, receive uniformaly full dose.

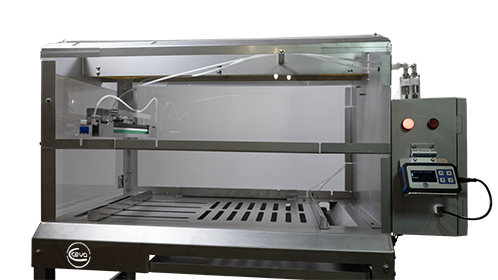

Automatic gel arm system

Gel droplet technology is the most efficient route of administration for the Immucox range.

A motorized arm, combined with an electronic dispensing syringe, ensures a homogenous & high quality gel droplet distribution. Optimum gel droplet allows high quality birds pricking & consequently high vaccine take.

Thanks to the Smart Hatch Spray & Gel, it is now possible to dispense gel in the most precise manner on a standalone machine without the need of hatchery automation.

Article

Go into the details of gel dispense technology in our featured article showing advantage of gel delivery system for coccidiosis vaccine

Gel arm dispense

The motorized arm enables consistent distribution from the beginning to the end of the crate.

Non operator dependent vaccination

The machine is fully electronically managed for complete control of all critical parameters to ensure proper vaccination.

The spray & gel syringes are synchronized with the dispensing arm and continuous monitoring ensures full crate vaccination. Whenever a deviation is identified by the system, an alarm alerts the operator.

Alarm system ongoing

All critical parameters are monitored, alerting the operator if any part of the vaccination process deviates from the correct sequence. Ensuring 100% vaccination coverage for all animals.

%20-%20Photo%20HMI%20(1).png?width=500&height=281&name=Picture%20alarm%20on%20HMI%20(low%20vaccine%20for%20example)%20-%20Photo%20HMI%20(1).png)

Automatic processing

Automatic machine controls also alert the operator to any unforeseen events, such as crate removal before the vaccination is complete, vaccine shortage in the containers, and also the number of vaccinations performed in a day, week, month, and more.

User friendly

The Smart Hatch Spray & Gel design allows any operator to start it within seconds; the vaccine priming and cleaning cycle are automatic. This streamlines the entire process, enabling anyone to use the machine with minimal training.

Operator easiness

To enhance user comfort, the machine is adjustable in height to accomodate various sizes.

.png?width=450&height=266&name=Logo-Connected-CHICK-Program-V2%20(2).png)

Supported by Ceva

C.H.I.C.K. program

Regular operator

training

Regular vaccination

quality audits

Frequent preventative

maintenance

-1.png?width=500&height=281&name=Design%20sans%20titre%20(3)-1.png)